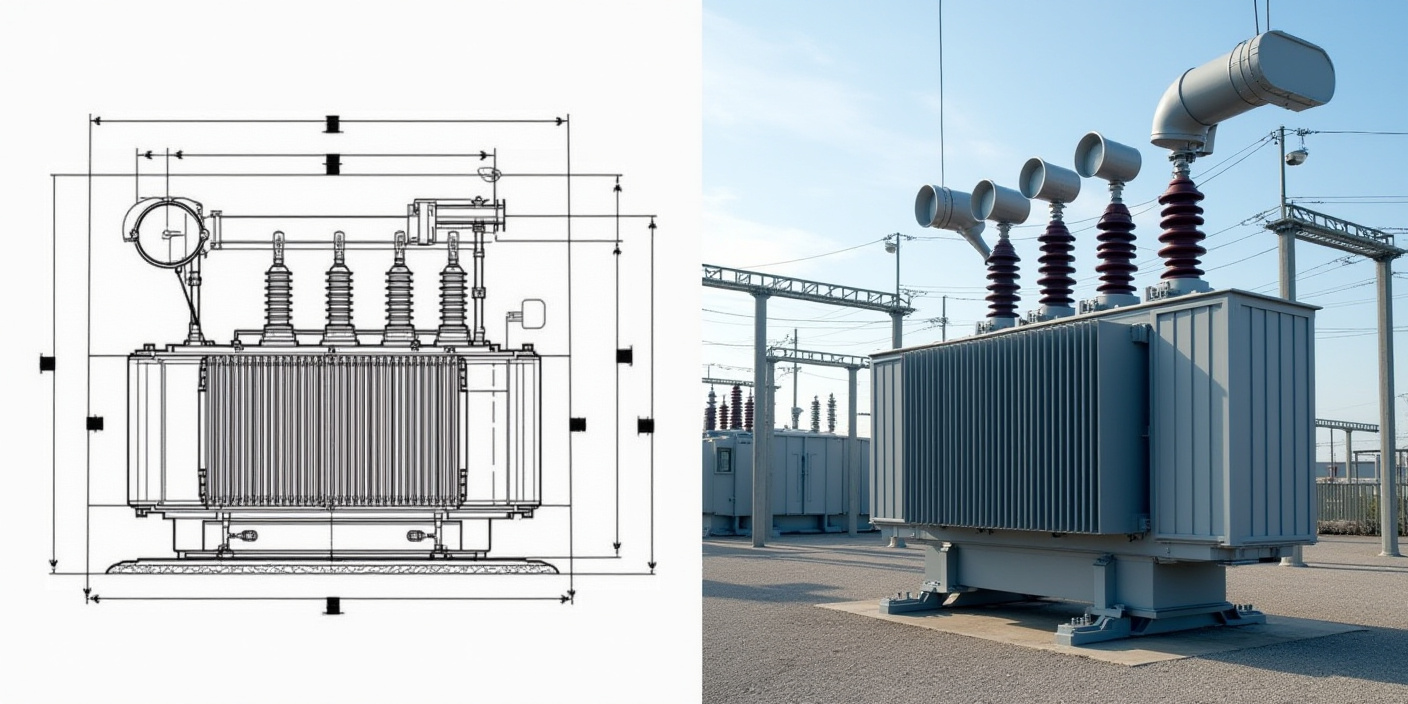

Why Amorphous Core Transformers Are Ideal for Industrial and Utility Applications

In the modern era of energy-conscious industries and utility providers, reducing power losses while maintaining reliable performance is paramount. Amorphous Core Transformers have emerged as a game-changer in energy-efficient power distribution, offering significantly lower core losses compared to traditional silicon steel transformers.

Manufactured by Smriti Enterprise, a leading manufacturer in electrical solutions, these transformers are engineered to meet industrial, commercial, and utility-scale requirements while maximizing efficiency and minimizing operational costs.

Design & Materials

The efficiency and performance of an Amorphous Core Transformer are directly influenced by its core design, materials, and construction:

- Core Material: Uses amorphous alloy steel with disordered atomic structure to reduce hysteresis and eddy current losses.

- Lamination Thickness: Extremely thin laminations (approximately 0.025 mm) allow for reduced core losses and high magnetic permeability.

- High-Grade Copper Windings: Ensures minimal resistive losses, excellent conductivity, and long-term reliability.

- Insulation System: High-quality insulating materials for primary and secondary windings ensure durability under voltage stress and thermal variations.

- Protective Enclosure: Rugged enclosures with anti-corrosion coatings provide protection against environmental hazards like moisture, dust, and extreme temperatures.

These design elements combine to create a transformer that is energy-efficient, durable, and reliable, even in demanding industrial and utility environments.

Types & Variations

Amorphous Core Transformers are available in multiple configurations to meet different applications:

- Distribution Transformers: Ideal for industrial and urban electrical distribution, ensuring low-loss energy delivery.

- Pad-Mounted Transformers: Suitable for outdoor installations in residential, commercial, or industrial areas.

- Pole-Mounted Transformers: Compact solutions for overhead line systems, minimizing footprint while maintaining efficiency.

- Oil-Immersed Transformers: Enhanced cooling and longevity through dielectric oil, suitable for heavy-load applications.

- Dry-Type Amorphous Core Transformers: Maintenance-free, eco-friendly, and ideal for indoor or environmentally sensitive locations.

Smriti Enterprise also provides custom-built transformers tailored to specific voltage ratings, capacities, and site requirements, ensuring perfect fit for every industrial or utility need.

Key Features & Specifications

The unique characteristics and technical specifications of Smriti Enterprise Amorphous Core Transformers make them highly desirable:

- Voltage Ratings: 11kV – 33kV (Primary) and 400V – 11kV (Secondary), customizable on request.

- Power Capacity: 50 kVA – 5000 kVA to suit industrial, commercial, and utility applications.

- Core Loss Reduction: Up to 70% lower than conventional silicon steel transformers.

- Efficiency: Exceeds standard energy efficiency benchmarks (IEC 60076-20 compliant).

- Temperature Class: Class F or H insulation for high thermal stability.

- Noise Level: Ultra-low audible noise, suitable for urban installations.

- Cooling System: Natural Oil Cooling (ONAN), Oil Forced Air (OFAF), or Dry-Type cooling options.

- Mounting Flexibility: Floor-mounted, pole-mounted, or pad-mounted configurations.

- Protective Devices: Optional Buchholz relays, pressure relief valves, and lightning arresters for enhanced safety.

These specifications ensure robust performance, minimal energy wastage, and long operational life.

Advantages & Benefits

Investing in Amorphous Core Transformers offers multiple advantages for industrial and utility operations:

- Energy Savings: Reduced core and no-load losses translate to significant annual electricity savings.

- Environmental Sustainability: Lower energy consumption reduces carbon footprint, supporting green initiatives.

- Cost-Effective: Reduced losses and longer lifespan decrease operational and replacement costs.

- Reliability: Superior design and materials ensure uninterrupted performance under heavy load and fluctuating voltages.

- Quiet Operation: Minimal noise pollution makes them suitable for urban and sensitive installations.

- Low Maintenance: Robust construction and high-quality insulation minimize routine servicing requirements.

- Compliance: Meets international standards for energy efficiency and safety, ensuring regulatory adherence.

By leveraging these benefits, industries and utilities can enhance operational efficiency, reduce expenses, and contribute to sustainable energy practices.

Performance & Capacity

Performance and capacity are critical when selecting transformers for industrial or utility use:

- Load Handling: Supports continuous operation at rated capacity with minimal heat generation.

- Thermal Management: Effective oil or air cooling maintains optimal winding and core temperatures.

- Voltage Stability: Ensures steady output voltage, reducing fluctuations that can damage sensitive equipment.

- Long-Term Reliability: Amorphous cores maintain magnetic properties over decades, ensuring consistent energy efficiency.

Smriti Enterprise performs rigorous testing on all transformers, including load tests, impulse tests, and thermal evaluations, guaranteeing top-tier performance under real-world conditions.

Installation Guidelines

Proper installation ensures safety, efficiency, and longevity:

- Site Preparation: Adequate foundation with vibration-free mounting and proper drainage.

- Grounding: Proper earthing to prevent electrical hazards.

- Positioning: Ensure clearances for cooling, maintenance, and safety compliance.

- Connection: Correct primary and secondary wiring with secure insulation.

- Protective Equipment Installation: Fit relays, fuses, and surge arresters as required.

- Initial Testing: Verify voltage, insulation resistance, and load behavior before commissioning.

Following these guidelines ensures optimal transformer performance and minimal operational risks.

Maintenance Guidelines

Regular maintenance maximizes efficiency and lifespan:

- Oil Check (for oil-immersed): Monitor dielectric strength, moisture content, and oil level.

- Temperature Monitoring: Ensure operating temperature remains within specified limits.

- Visual Inspections: Check for leaks, corrosion, and structural integrity.

- Electrical Checks: Test insulation resistance, winding continuity, and protective devices.

- Cleaning: Remove dust or debris from core, windings, and cooling fins.

Proper maintenance guarantees reliable energy delivery and reduced downtime.

Applications

Amorphous Core Transformers are widely used across industrial and utility sectors:

- Industrial Plants: Manufacturing, refineries, chemical processing, and heavy machinery.

- Utility Distribution: Urban and rural electrical grids, ensuring energy-efficient power delivery.

- Commercial Complexes: High-rise buildings, shopping malls, and office complexes.

- Renewable Energy Integration: Solar and wind power systems requiring low-loss transformers.

- Infrastructure Projects: Airports, railways, and highways needing reliable, low-loss power supply.

These applications highlight the versatility and strategic importance of amorphous core transformers.

About Smriti Enterprise

Smriti Enterprise is a leading manufacturer of high-efficiency Amorphous Core Transformers, known for engineering excellence and commitment to sustainability.

Our pillars of strength include:

- Advanced Manufacturing: Precision core cutting, winding, and assembly for consistent quality.

- Customization: Transformers designed to meet unique voltage, capacity, and site-specific requirements.

- Global Standards Compliance: IEC, BIS, and energy efficiency standards for industrial and utility use.

- Experienced Technical Team: Expert engineers for consultation, design support, and post-installation services.

- Eco-Conscious Practices: Use of low-loss cores and energy-efficient designs to reduce environmental impact.

Choosing Smriti Enterprise ensures superior efficiency, durability, and operational reliability for every industrial or utility application.

FAQs

Q1. What is an Amorphous Core Transformer?

A transformer using an amorphous alloy core to reduce hysteresis and eddy current losses, enhancing energy efficiency.

Q2. How is it different from conventional transformers?

Amorphous cores have up to 70% lower no-load losses and are more energy-efficient compared to silicon steel cores.

Q3. Can these transformers be used in outdoor installations?

Yes, with appropriate oil-immersed or weatherproof dry-type designs and protective enclosures.

Q4. What maintenance is required?

Regular inspections, oil testing (if applicable), temperature monitoring, and electrical checks ensure longevity.

Q5. What industries benefit the most?

Industrial plants, utility grids, commercial complexes, renewable energy projects, and infrastructure developments.

Q6. Are these transformers cost-effective?

Yes, reduced energy losses and longer operational life lead to significant cost savings over time.

Q7. Why choose Smriti Enterprise?

They combine advanced manufacturing, customization, compliance with global standards, and technical expertise to deliver high-efficiency, reliable transformers.